When it comes to embroidery thread tension, a number of embroiders seem puzzled when it comes to flawless embroidery and a precise learning of adjusting and maintaining thread tension is a skill every embroider should perfect before going into the field. Once this skill is perfected, a prominent difference in production and betterment in quality of the product can be seen. Very often a design appears to be better with a slight improvement in the tension of embroidery thread. A lag in thread tension can cause multiple problems and an improper knowledge of the relationship between the top and the bottom thread can make it impossible to fix the problem.

How Will I Know If The Thread Tension Needs Adjusting?

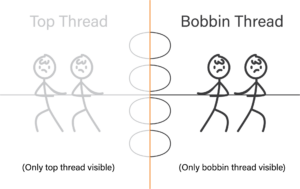

For a stitch to be formed, the needle carrying the top thread passes down the hole in the needle plate and connects with the bobbin thread. This forms a loop directly behind the eye of the needle. If the tension of the thread is set properly, the returning needle will have a tightened thread. In case the tension is too tight, the thread can snap. In the presence of a burr on the edge of the needle hole, the thread can split as it is coming up. Therefore, it is important to keep balance between your upper thread (top thread) and your lower thread (bobbin thread). Imagine the two threads are playing a game of tug-of-war, in order to form a lock, the upper and the lower thread need to maintain a slightly tense grip to have an optimum balance between them.

Upper Thread Tensioning

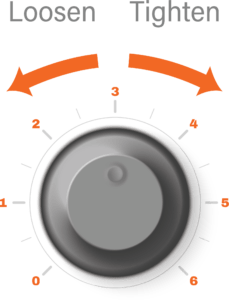

Correct thread tension is essential for vivid, attractive and solid design construction. Most of the thread breakages occur due to inappropriate thread tension set during embroidery. The upper thread tension is adjusted via a thread tension dial.

Correct Tension In The Upper Thread

The tension of upper thread is right when the upper thread is just visible at the back of the fabric by the edges of the bottom thread. (1) shows face of the fabric and (2) shows the back of the fabric

When The Upper Thread Is Too Tight

Here, the bobbin thread will be visible at the face of the fabric. In this case, decrease the upper thread tension.

When The Upper Thread Is Too Loose

In this case, a lot of upper thread will be visible at the edge of the bottom thread in the back of the fabric. To adjust. increase the upper thread tension.

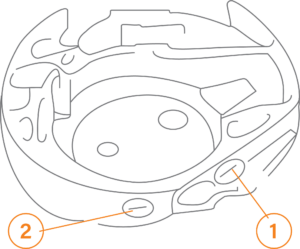

“In order to maintain the correct thread tension, you need to ensure the proper mounting of bobbin. Also, if the desired design accuracy is not being achieved even after adjusting the upper thread tension, refer to below “lower thread tension adjustment” for the required results”

Lower Thread Tensioning

If the desired level of tension is not attained through upper thread tension dial then try to adjust the lower thread tension by tightening the screw in the bobbin case.

Correct Tension In Lower Thread

In this case, the upper thread slightly appears on the back side of the fabric.

When Lower Thread Is Too Loose

It’ll look the same as when the upper thread tension is too tight, with the lower thread appearing at the front of the fabric. Increase the below thread tension by rotating the screw clockwise.

When Lower Thread Is Too Tight

In this case, the upper thread will excessively show at the back of the fabric. The tension can be made just right by loosening the screws.

Bobbin tensions should be between 18 – 22 grams. When adjusting the lower thread tension, be sure to remove the bobbin from the bobbin case. If the problem persists, ensure a damaged bobbin case is not in use. Other reasons may include damaged needles, as old needles can produce burr and uneven designs