Needles are an undeniably essential feature of machine embroidery. With a multitude of choices and lots of conflicting information on the internet, selecting the right kind can be a daunting task! Here, we have put together a guide to give you a clear idea of the most important aspects you need to consider before selecting the correct needle for your machine embroider.

“It is significant to change the needle regularly”

Which factors i need to consider before selecting any needle?

Before selecting an embroidery needle, you need to closely consider certain specifications of your embroidery machine along with a close consideration of the kind of fabric, thread and stabilizer involved. These are the main factors which determine the point and size of the embroidery needle your project needs. By using the correct needle type, you will be able to eliminate all the possible thread breakages and embroidery design failures. The result will be a smoother and crisper design.

“A lot of needles are required during an embroidery operation as many stitches are made per minute and each stitch must perfectly penetrate the fabric, stabilizer, and occasionally adhesive”

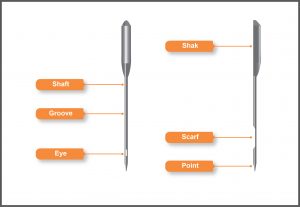

Anatomy of an Embroidery Needle

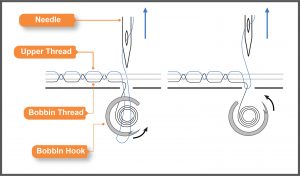

How a stitch is created?

The creation of a stitch starts when the embroidery needle enters the fabric and reaches down to its lowest point. Here, the bobbin hook slides into the scarf, catching the upper thread on its way and then revolves it around the bobbin and the bobbin thread. The thread is then pulled into the fabric, completing an embroidery stitch.

Mechanism of Stitch Formation

Selection of needle based on needle type

The type of needle plays a vital role in selecting the kind of needle for the embroidery project in hand.

Needle Size

Needle size refers to the diameter of the shaft. The higher the number, the bigger the shaft. The measurement is done using two systems:

The American system and the European system. The American system uses 10, 11, 12 etc. cm, as sizes while European system uses 70, 75, 80 etc. Sometimes measurements listed with both systems are written as 75/11, 80/12 or 85/13.

The European system is based on measurements in Millimeter. The size is multiplied by 100 to get the final figure. For example, 0.8 mm is listed as size 80 in the European system.

The size of the needle depends on the type of fabric, the thread used and the type of embroidery to be done. For sewing, the most common size used is 80/12 and for embroidery it’s slightly smaller at 75/11

Common sizes available in embroidery needles are: 75/11, 80/12 and 90/14. The lighter the weight of the fabric, the smaller the size of the needle to be used. The heavier the fabric GSM, the larger the needle to be used.

If the embroidery thread being used is heavier, a larger needle is to be used. Heavy threads need a larger needle eye to pass through. The groove of the needle also needs to be larger in order to hold the thread in place during operation.

The chart below can be used as a hands-on guide for selecting a needle based on its size for different fabric types

80/12

75/11

80/12

90/14

Quilt Cottons Batiks Denim Satin Linen Heavy Fleece “In case of thread breakages, thread shredding, or a low-quality stitch, the first step to the rescue is to change the needle”

Needle Point

Needle types vary for different types of fabrics and are not just limited to the needle size. The needle point type.

Embroidery needles are exclusive in different ways. The needle’s eye is bigger than the eye of a sewing needle that is the same size. The needle point is chosen depending on the type of fabric in use. There are three basic types of embroidery needles based on the tip/point:

Sharp Embroidery Needles are used for tightly-woven fabrics such as cotton quilts and pure cotton apparel. The sharp needle is designed to pierce through the fabric precisely in every penetration.

Ballpoint Embroidery Needles are used for knitted fabrics and help in preventing the formation of holes in the fabric. The tip of the ballpoint needle is designed to push the fabric away from the center of the needle rather than penetrating it and forming a hole.

Universal Tip Embroidery Needles are somewhere between a sharp embroidery needle and a ballpoint embroidery needle. They can be used for both woven and knitted fabrics. The tip is able to penetrate the woven fabric but isn’t sharp enough to form holes in the knitted fabric.

Take Away

A lot of needles are required during an embroidery operation as many stitches are made per minute and each stitch must perfectly penetrate the fabric, stabilizer, and occasionally adhesive, therefore it is significant to change the needle regularly. In case of thread breakages, thread shredding, or a low-quality stitch, the first step to the rescue is to change the needle. Despite being easily overlooked, needles are one of the most important aspects of the embroidery process.