Embroidery on leather is wonderful, an age-old tradition which has seemingly become lost to modernized machinery and uniformity in design. However, if we follow the basics accurately and clearly of combining leather and the art of embroidery, this craft still carries with itself the potential to create mesmerizing products.

Interestingly, many embroiderers are afraid of performing leather embroidery. The intricacy of this procedure intimidates the hearts of even the most experienced embroiderers as they feel they have only one chance to get it right. One wrong punch, one wrong stitch and they could blow it! If a single stitch goes wrong, the error is visible to everyone and the holes in the leather are irreversible.

Regardless, where fear ends, monetary success begins (potentially). The good thing about leather embroidery is that the profit potential is more, since the availability of leather embroidered products is limited in many markets. This demand supply gap presents itself with various opportunities, allowing embroiderers to try their hands on different materials of leather and designs before introducing their products in the market. Different types of leathers react differently to embroidery among other factors which also depends on how leather is tanned.Two Basic Techniques Of Tanning Leather

Vegetable, Oak Or Bark Tanning

This process uses a metal die or mallet to impress motifs on the surface of the leather. The process produces hard surfaces.

Chrome-Tanned

This process uses chrome salt in order to produce chrome-tanned leather. This technique is suitable for embroidery upholstery or garment leather and has a soft and supple surface.

Factors Affecting Leather Embroidery

Machine embroidery on leather is not scary, if the embroiderer follows the instructions and tips accurately and invest enough time as it is time taking process, the embroiderer can excel at it easily. This tutorial provides you with a guide on how to smoothly carry out embroidery on leather.

Embroidered leather can result in great looking products and in no time, you can become a pro at leather embroidery, running your own successful business.

It is important to have all the correct tools along with scraps where you can start your practice before directly punching holes on to you beautiful leather.

Following are the basics to keep in consideration before starting embroidery on leather.

Leather Type

Leather comes in different types such as cowhide, suede, lambskin, and buckskin. Each leather has its own distinct qualities of thickness and stretchiness. You can avoid thin and soft leather since it will be tricky as it is sensitive to embroidery machines. Fake leather will give you more variety, in terms of denser designs, than the real leather.

Selection Of Design

Due to the delicate behavior of leather, it is best to use light and sheer design. Heavy design with satin stitch will leave the needle marks and the embroidery could actually perforate and tear off the leather.

Needle Selection

Needle selection is one of the most crucial step. You must use needles with a very narrow wedge to make it easy to penetrate through leather, vinyl and different materials. Standard size that can be used is an 11/75 leather needle. Make sure you buy a flat shank needle for home machines and a round shank for industrial embroidery machines

Hooping Leather for Embroidery

Prior to hooping, shower your temporary adhesive on the stabilizer and smooth out your leather on top of the backing. Put the cotton or muslin fabric on top of the leather to avoid the hoop marks. Leave the embroidery’s middle part uncovered. Calfskin is touchy to over-fixing of the band, so stay away from this by opening the loop hoop more extensively than normally required. Once the hoop is fixed, the changing screw will barely be enough to keep it secure for weaving. After you are done, remove it from the loop straightaway. The more you keep it hooped, the more you increase the danger of making an imprint on the leather.

-

Machine Speed

Speed of the machine should be kept at a medium; neither too fast nor too slow. Moderate speed will easily pierce the leather more effectively, with around 340 – 360 stitches per minute.

Leather Embroidery Process

Digitizing For Leather Embroidery

Digitizer helps in transcribing the given instructions related to the selected logo to its original form by using a particular thread on the leather. For this purpose, digitizing software is used to make the design which needs to be applied. The digitizer file also contains instructions about the stitch type, making it even more easy and interesting to use. An integral point to remember is the three types of stitches that can be carried out on a machine are satin, fill and run stitch.

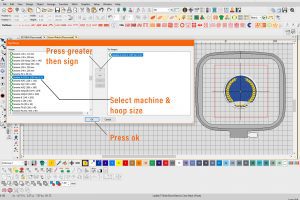

Logo/Design Uploading

The first step is to upload the logo to the digitizer software and make necessary corrections so that the machine will follow the given design.

Size Selection

After the logo is uploaded, you need to put the dimensions in the software which is to be implemented. Remember to check the size and shape of the design before giving the command.

Stitch Type Selection

After giving the size dimensions, select the type of stitch according to the leather you have chosen.

Stitch Direction

To give a direction to the embroidery machine, stitch direction is needed. To attain variations in patterns and designs, different types of stitch directions must be provided by giving step by step command to the system. Any gap in the step will result in not achieving the required pattern of embroidery on leather.

Required Colors Of Thread

This part is fun; look around and explore different threads in different colors. The color of the threads must be decided to get the desired aesthetics. The color shade must be selected by comparing the desired color with the color matching chart.

Transferring To Embroidery Machine

After all the commands are set, the file is then entered in the embroidery machine. The transfer of data can be done either by a USB or through different software’s.

Giving Command To Embroidery Machine

After entering the file in the embroidery machine, give the exact commands of needles and colors to the machine and then put the leather in the frame of the embroidery machine.

Required Product Or Embroidery Design

With patience comes great outcomes. After performing all defined processes accurately, your dream design will be created successfully.

However, if you don’t get the desired result, you can always make changes to your input and attain the output accordingly

Conclusion

Don’t let the above information and technical terms scare you away. The art of embroidery on leather gives a unique characteristic to the products. It also enhances the quality and aesthetics of the leather products. The customers get attracted by the embroidery on leather as it creates a very attractive perception in the viewer’s eye. If you find this helpful,