Thread

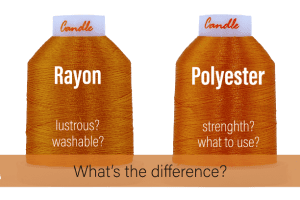

Polyester Vs Viscose Rayon Embroidery Thread

Are you aware of the fact that different types of embroidery threads are available in the market?

Various sorts of machine weaving strings are also available.

The ones mostly used generally are created from viscose or polyester. Unfortunately, there isn’t a lot of data available which aids in understanding the elements and impediments of these types of thread and are hard to track down.

Therefore, we have made this speedy and practical guide for you.

Find out about the similitudes and contrasts between polyester and thick machine strings, and ultimately learn which is most appropriate.

Numerous embroidery thread types exist for creating different appearance and feel, the assembling measures, the upkeep and use of the material merchandise, expenses and usefulness, natural effects, and quality. The forms utilized the most are viscose and polyester threads; each has its rates and limits hence ideal for various tasks. Let’s have a look at different aspects of viscose vs. polyester embroidery thread.

Viscose Rayon Embroidery Thread

The Rayon thread gives a beautiful and delicate looking design, which are delicate to wear and can be washed in water up to a temperature of 203 degrees. Rayon has a high gloss and is considered to give a high sheen, and remains soft even at a high stitch count.

Polyester Embroidery Thread

The Polyester embroidery thread has the feature of running smoothly without breaking the thread even at high speed. Another prominent attribute of this thread is that it does not fade after laundry and is very economical.

It is highly durable and contains profound tensile strength. Do you know it can even withstand bleach and resist the change of its shape?

The exciting feature about Trilobal Polyester is that it has a sheen similar to rayon.Which Option Is Better Between Viscose And Polyester Embroidery Thread?

Both threads have stunning results and many tones and both functions admirably on various texture types but because of less thread breaks.

Polyester is preferable if you want the machine to run smoothly.

Try not to be hesitant to test a thread before you using it if you are uncertain of the quality or have never attempted it. We have, likewise, discovered that as the notoriety of polyester weaving thread has expanded, organizations produce lower valued, lower quality thread.

Some polyester threads even stretch! However, the cost per spool looks extraordinary; we frequently discover embroiderers abhorring polyester threads because, not intentionally, they were utilizing a polyester thread knock-off.

Viscose threads are gentle with the components of the embroidery machine when they come in contact with and cause low friction and no residues. Viscose threads generally need a lower tension than polyester.How To Choose The Right Embroidery Thread?

Should You Be Concerned Regarding Raw Material And Its Environmental Impacts

Economically and environmentally, no doubt, viscose is natural and is obtained from the wood of certain trees instead of being chemically processed to give an organic solution from which the thread is spun.

Mostly, raw material of the viscose thread comes from certified forests that are responsibly managed. They behave like artificial silk along with providing affordable natural features and a unique softness and shine.

Polyester embroidery threads are being engineered, with artificial items acquired from oil. They are grown particularly for perseverance and protection from substance handling, which may require cleaning for configuration.

They also offer value comfort and act as the ideal decision for adorning products that need such properties. When you choose polyester, pick marks created in ensured industrial facilities to save assets such as water and power and use them productively.What Kind Of Shiny Appearance Do You Need For Your Design?

Viscose thread unfolds in the light with a beautiful, silky, and subtle sheen, whereas polyester has an intense and more straightforward shine. Both thread types are not made the same way, even though both are very shiny and offer a slightly different appearance.

If you are looking for multi-dimensional and depth to design or create shimmer effects, viscose embroidery thread will be your best choice. Many fashion and home décor applications require features that are present in viscose thread.

If the light effect is not needed in the design, either Polyester or Rayon can be used.What Kind Of Embroidery Feel Should You Look For?

There is a quite difference in the softness of Viscose and Polyester. Consider viscose threads as they are flexible and perform well in intricate design or dense stitch. They are delicate with the parts of the machine they interact with and cause low grinding and no deposits.

The plans will be wonderful to the touch, precise, exact, and skin-accommodating.

Polyester threads have a more complex touch, run a bit stiffer, and feel a bit heavier, making them genuinely appropriate for more rigid materials. Viscose embroidery thread needs a lower pressure than polyester.On What Material Will Your Embroidery Be?

Viscose threads are all-rounders; they offer a ton of opportunity to pick the materials or join types and headings and are more qualified for thick textures than polyester yarns. They generally work routinely and are excellent on weighty to fine, light textures. They likewise cause practically no circling or string breaks.

Polyester threads may feel a bit more grounded and grating and are entirely reasonable for items with comparative properties, like covers, rucksacks, identifications, limited time things, and hard manufactured materials.How Is Embroidery Thread Being Processed During Cleaning And For Design Special Effects?

The perseverance of polyester threads is notable. They can withstand mechanical cleaning techniques, powerful cleansers, bleaching, and stone washing.

Viscose permits the utilization of standard cleaners that don’t contain bleaching specialists. Both threads can withstand high washing temperatures of 95 °C and have superior protection from high pressing temperatures.Points To Be Considered During The Selection Of A Particular Brand Embroidery Thread

As an embroiderer, you are required to check the following general features that determine the quality of the embroidery thread for smooth running on the embroidery machine without breakage and wear and tear.

Visualization and recognition of threads certificates

Availability of shades

Compatibility with fabric material

What kind of appearance do you desire

Conclusion

As a result of their power and strength, polyester embroidery threads are preferable for work wear, bedding, youngsters’ clothing, towels, white materials, outerwear, bathing suits, and even pants! Due to its superior tensile strength, it is perfect for any application in commercial and home machines. It is also used for different items that should be bleached or need to withstand brutal synthetic compounds or industrial washing. Viscose Rayon is additionally reasonable for corporate style, however just when no fading is fundamental.